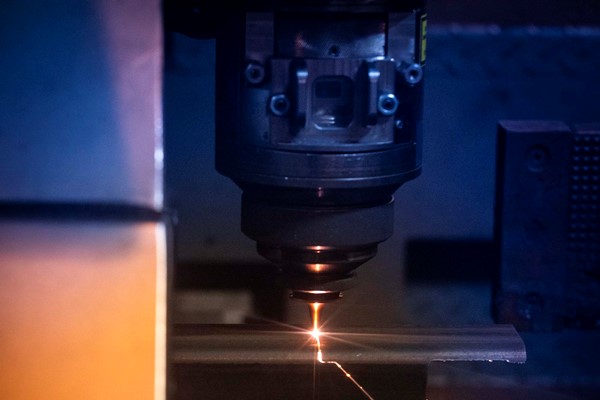

Laser tube cutting

Our capacity

We can handle laser tube cutting output lengths up to 8.5 m, and finished components up to 6.5 m; we can handle dimensions from 12 mm up to 220 mm in diameter and weighing up to approx 40 kg/m.

2D laser tube cutting

2D laser tube cutting provides a fast, cost-effective process suitable for all dimensions. It uses a fixed cutting head that moves along two axes and which provides perpendicular cut surfaces. The machine is very fast, flexible and provides high precision, which creates many possibilities.

3D laser tube cutting

3D laser tube cutting uses a movable cutting head that can handle complex machining previously not possible with a laser cutter. Pieces can be finished fully mitred and prepared for welding or cut with bevelled grooves and prepared for bending with a minimum of welds. The magazine feeder and single-piece infeed makes the machine suitable for very large series, prototype manufacturing or small production runs.

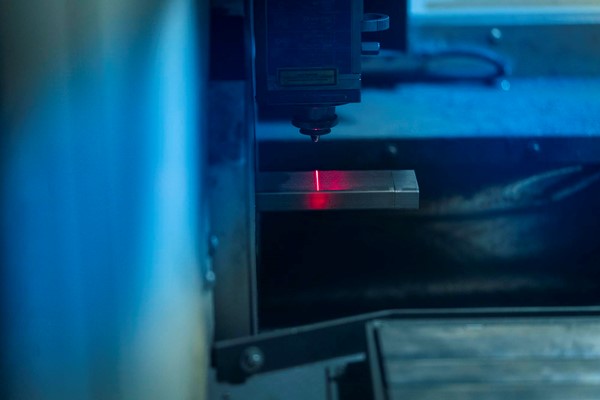

Active Scan

Our laser tube cutters are equipped with the Active Scan optical system, which identifies and compensates for imperfections in the material such as bent or twisted tubes. This safeguards our desired tolerances, raises quality and checks the precision of everything we deliver.

Spatter-free tubes

We can supply tubes fully free from dirt and internal laser spatter. Using a special spoon-shaped tool that adapts to tube diameter, we suck out all laser spatter that occurs during the process. The surface is cleaned without the need for further processing.

Laser tube cutting

Laser tube cutting

Cutting

Cutting

Machining

Machining

End machining

End machining

Welding

Welding

Shot blasting

Shot blasting

Cleaning

Cleaning

Warehouse

Warehouse

Design

Design

Measuring

Measuring